How We Make Custom Embroidered Patches

Custom embroidered patches are a way to stand out and provide information. Have you ever wondered how they're made? Take a look at the process.

Custom embroidered patches are a great way to indicate rank, reward performance, promote your brand, make a political statement and many more uses. They offer a blend of practicality and artistic expression.

Have you ever wondered how embroidered patches are made? It’s an intricate process, one that’s highly automated. Let’s take a step by step look at embroidered patch creation from your design to the time your patches are shipped to you.

Design Creation: Transforming Ideas into Art

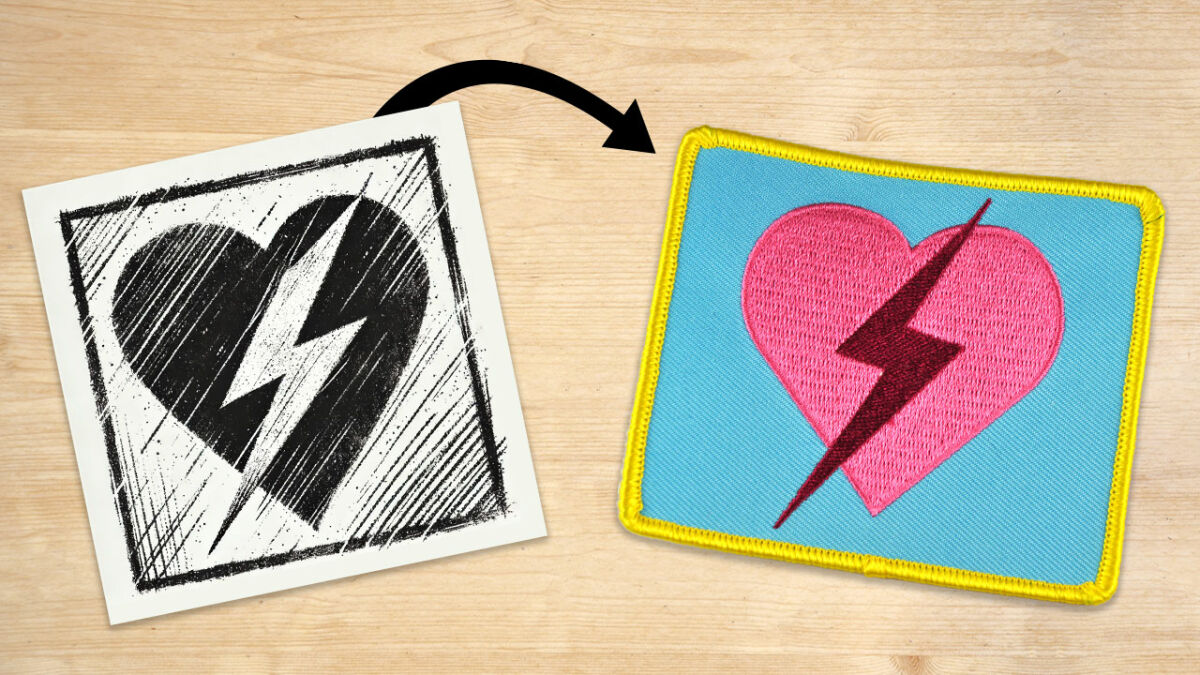

Every patch starts with an idea. Whether you have an existing company logo, a thought for a new one, or a vision of what your patch could portray. You might design it yourself, or maybe you hire a designer to create it for you. Either way, it all begins there.

Next comes a discussion of patch dimensions, thread and background colors and border styles to match the vision. The graphic artists at your patch provider will help with this step. This might involve adding or deleting details from your design to ensure it looks the best it possibly can and conveys exactly what you want.

Your patch provider will create a digital proof of your design, using graphics software. They’ll email it to you for your approval. This ensures that your patch will look just the way you want it to when it’s produced.

Digitization: Making Your Design Machine-Readable

After you approve the patch design, your provider will convert your design into a digital file that computerized embroidery machines can read and create. This involves turning every aspect of your patch, including the sequence, direction and density of each stitch into a digital file the machine will follow exactly. This process is called digitization.

One thing that might surprise you about digitization is that it is unique to every embroidery machine manufacturer. Your provider will use equipment from a specific manufacturer, and a file digitized for that brand won’t work on a different manufacturer’s machine. You don’t have to worry about it. The patch provider will ensure your patches will be produced correctly, no matter what brand of machinery they have.

Material Selection

The backing material for your patch will depend on both the style and use of your patches. For example, military uniform patches might feature a different backing that fashion apparel patches would. Twill is the most common backing, and felt and leather are also popular. Each has its unique characteristics.

- Twill provides a smooth, durable surface for most patches.

- Felt adds a soft, vintage feel for specialty designs.

- Leather offers a premium option for luxury or rugged looks.

Thread Choices

Your design will determine the thread colors your embroidered patch creation. Your provider will match the colors with your design. If you need to match colors precisely, such as for an existing company logo, they will use the Pantone color matching system to ensure an exact match.

Setting Up the Embroidery Machine

Once all the patch specifics are set, your design will be uploaded to the embroidery machine. Operators will thread the machine and set it for the proper patch size, thread tension and stitch density. Next, the operators will secure the backing material into an embroidery hoop or frame to hold it in place during the embroidery.

Embroidery: The Custom Patch Process Brought to Life

Once the embroidery machine is started, it functions fully automatically to create your patches. Multiple needles, each threaded with a different color precisely follow the digitized instructions, crafting the finished product. Machines will typically have multiple embroidery heads to create many patches at once rather than one at a time.

Border Finishing: The Final Touch to Embroidered Patch Creation

When the embroidery is finished, the custom patch process continues with adding a border to enhance the patch appearance and prevent fraying. The two most common border types are merrowed and hot-cut.

A merrowed border is the classic patch border, featuring a raised look that emphasizes distinctness between the patch and the garment it’s attached to. It’s sewn on a Merrow® brand specialized sewing machine. It creates a clean, timeless look and prevents the patch thread from fraying. This border style is best suited to traditional geometric patch shapes.

A hot-cut border uses a hot edge to seal the borders of the patch to prevent fraying. This style creates a flatter patch with less visual separation from the garment it’s attached to. It’s best suited for irregular or custom-shaped patches

Attachment Styles

How you intend to attach your patches determines the next step in embroidered patch creation. If you plan to sew on your patches, no further action is required. If you intend to iron on patches, the provider will apply a heat-activated adhesive so it will be ready for you to iron on.

For Velcro® hook-and-loop fasteners, the provider will attach half of the fastener to the back of the patch. You will be able to attach the other half to the garment when you receive the patch.

Temporary or one-time use patches, such as for special events or promotions can receive a peel-and-stick adhesive, and will be ready for use when you receive them.

Quality Control, Packaging and Shipping

The last step in the custom patch process before packaging and shipping your patches to you is inspection. Every patch is checked for proper stitching, alignment, that edges are secure and that the appropriate attachment options are in place. Patches that don’t meet the rigorous requirements are rejected and replaced.

Finally, the completed patches are packed carefully and shipped by the appropriate method to the address you specify, ready for your application.

A Blend of Art and Technology

There you have it – the embroidered patch creation process from start to finish. From the art of designing through the technology of manufacturing, each step is geared toward giving you a top quality product that fits your needs perfectly.

The key to success is to have a dependable patch provider. At Patches4Less.com, we’re committed to offering the best custom patches you will find anywhere. Our dedication to precision design, exact manufacturing and rigorous quality control enables us to offer you outstanding patches at excellent prices.

We also back up every single patch we sell with our 100% Satisfaction Guarantee. Should you find any patch you buy from us to be defective in either workmanship or materials, we will replace it at no extra cost to you.

Let us show you how easy embroidered patch creation can be! Call us toll free at 866-847-2824, email us at [email protected], or fill out our no-obligation free quote form. We look forward to serving all your custom embroidered patch needs.